I was a part time carpenter few years ago and I always loved to make different products with wood. When I started training as carpenter (part time), there was no complex technology (such as CNC machines) as we have today. Thats why I always found some tasks difficult and it was very time consuming for me. However you don’t have to worry about it now days as we have complex machines such as CNC router, which is the best machine to make your life easier.

Look at the image above, now imagine trying to cut the owl out by hand! It would take some great skills and most importantly very time consuming. So thats why I think CNC is an amazing gift in the world of technology, no less than a great reward for those who work on wood. Because it was a laborious task that was a challenge for big companies, it saved companies a lot of labor fees too.

In the world of industrialists, this machine has caused lots of controversy as these machines have totaly eliminated numerous labor jobs. This is because before it would have required a large number of staff to complete the job but now less labor plus these machines can do the job lot faster.

I beleive working as carpenter is one of the most beautiful professions in the world, simply because wood has a significant role in the beauty of the world. Without woodwork we would have ugly doors, gates, chairs and most importantly tables. You can also make a wooden key chain, a Tiffany box, a wooden watch, a wooden watch, etc.

If you want to make your house look beautiful then you can bring beauty in the house through wood such as wooden chandeliers, wooden chairs, wooden bouquets, wooden utensils, wooden toys, wooden shops. These are the best ideas for home beautification۔

The easiest machine to do this is a small CNC router and it is a must have in your home. You can buy it at the lowest price according to your budget. I can guarantee you that after that your work will be much easier.

If you want to decorate your home with your woodwork, you will find many videos on youtube, through which you can make beautiful wood products. However it doesn’t sound as easy as it looks, so make sure you have someone with experience to help you. It’s also important to use caution to avoid any injuries. Although CNC Router table is probably the safest for carpentry.

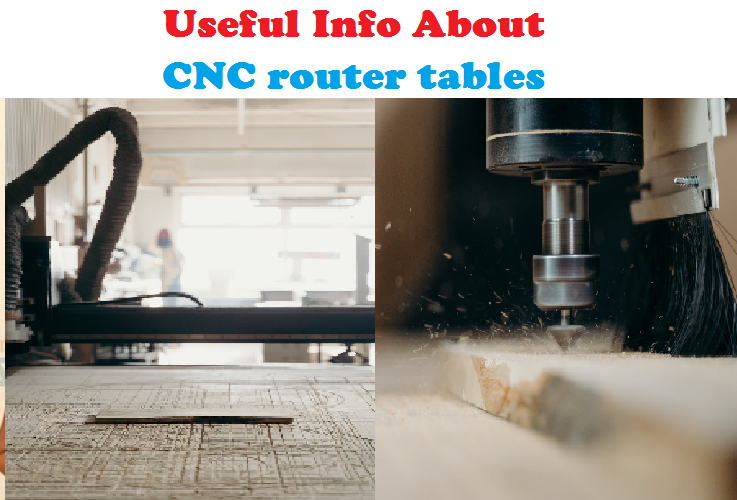

How to produce a design on PVC and wood with CNC router machine:

-

To start with you need to have Coreldraw or AutoCAD software installed on the computer. This is because the desired text or shape can only be designed by these two programs, which then it is passed on to the machine for it to be “lasered” on Plexiglas. Standard samples can also be found on the Internet.

- Then we take the DXF output from the desired design and cut it on different materials (wood, steel, iron, Plexiglas, etc.) by using the laser cutting machine (metals or non-metals).

Note: Regarding Plexiglas, it should be said that there are different brands in the market, the best type of Plexiglas belongs to Taiwan, and it is better not to use low-quality polish or Chinese brands, because the Plexiglas will lose their colour and we will end up with a ugly dull design.

- After cutting the design by the laser machine, it is time to glue the edge of the wood. Some panel workshops use the CNC machine to glue the edge of the cut-out pieces. However some panel producers who use CNC machine will inevitably have to use their hands for different parts of the letters/design that the machine is not able to make. This is why you need to have the required skills before start using these machines (even for the small ones made for home).

- After making the letters/designs, it is time to cut the letter substructure which is made of PVC. First the letters made of Chelnium or wood are placed on pvc and then the letters are marked around the PVC which then PVC is cut with a saw.

- To install the letters on the board, first the PVC sheet is screwed on the background of the board, and then the SMD lamp wires are taken to the back of the board. In the final stage the letters are installed on the PVC sheet and the power supply is placed behind the board, then the cable of the ones brought from the front of the panel are connected together, which is then connected to the power supply.

Hopefully you find this article helpful.